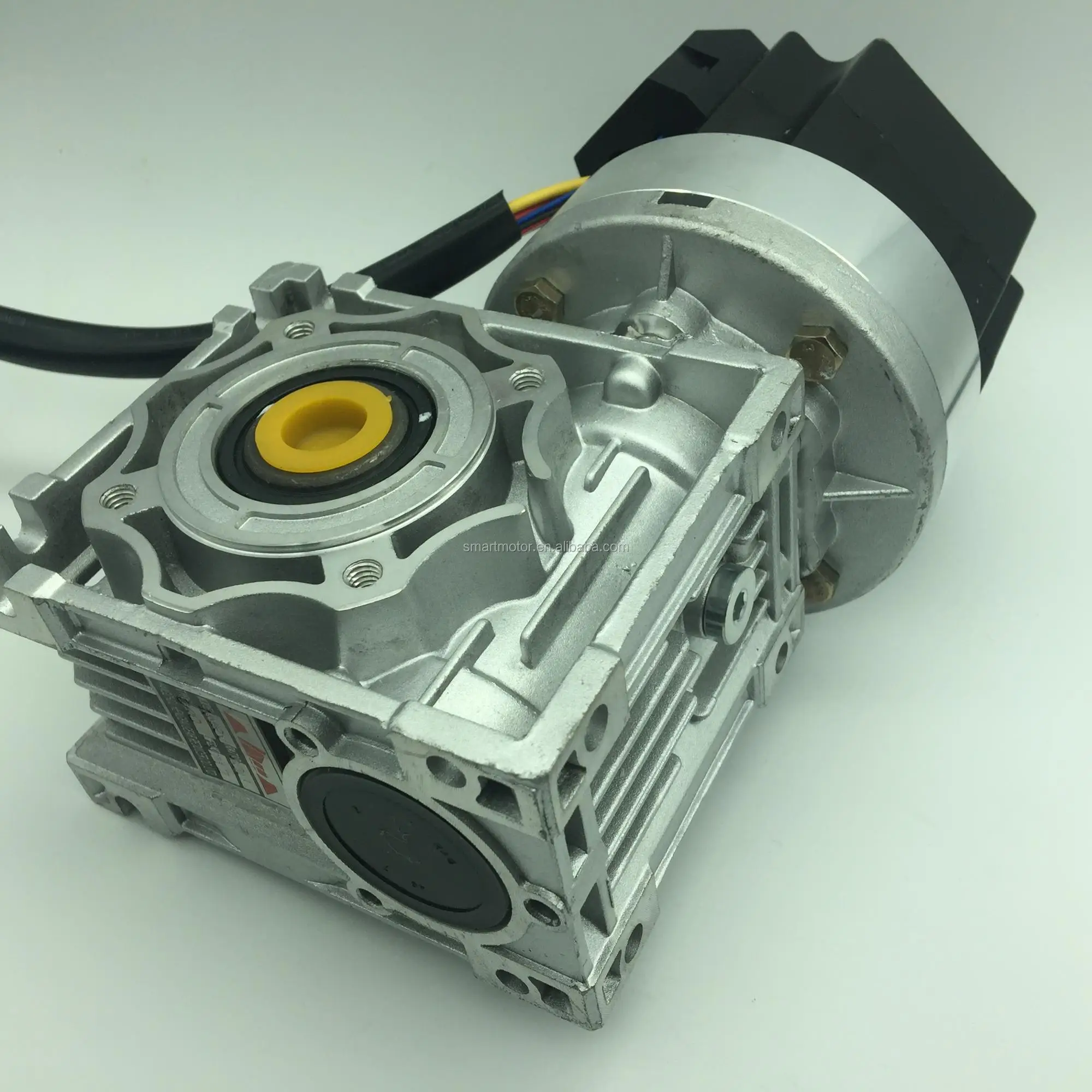

DC 24V 5RPM High Torque Turbine Worm Gear Box Geared Motor 634JSX634

1 2 3 4 5 ISL Products' Worm Gear Motors are designed to generate high torque in a small package size. Worm Gear Motors consist of a worm gearbox coupled with a dc motor. They offer many benefits, including high torque transmission, compact design, and self-locking ability. Additionally, worm gearheads can transfer motion in 90 degrees.

WFF050SH11180 DC 5V12V 6200RPM16800RPM High Speed ,Micro Mini 050

November 6, 2023. Worm gears are power-transmission components primarily used as high-ratio reductions to change the direction of shaft rotation and to decrease speed and increase torque between non-parallel rotating shafts. They are used on shafts with non-intersecting, perpendicular axes. Because the teeth of the meshing gears slide past each.

.jpg)

Diamond Gear Co. Heavy Duty Motorized Worm Gear 174WG409

UNIVERSAL worm gear units impress with their high power density and compact design. In addition to the basic universal housing, we offer an extensive line of bolt-on components to customize the product including torque arms, shaft covers and output flanges. These can be easily field installed, but we will also be glad to assemble the individual.

Helical worm geared motor SRM 120 Watt 230/400V 50Hz i=12.51 output

Product details Product configurator Worm gear motors to the E-Shop NORD Geared Motors with Worm Gear Units - Tailor-made drive technology Worm Gear Units from NORD DRIVESYSTEMS especially show their strength in applications in which high gear ratios are necessary.

86mm BLDC Worm Gear Motor with NMRV Gear reducer High Torque Large

A Comprehensive Guide on Worm Gear Motors. A worm gear motor, also known as a worm drive motor, is a type of gearbox that uses a worm to reduce speed and increase torque. In this comprehensive guide, we will delve deep into the world of worm gears, their applications, and best practices for choosing and maintaining them..

Worm geared motor HMD/II basic version gearbox size 030 n2=200 rpm 0

Worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. They transmit motion from worm to gear and cannot be reversed. For gears and worms to mesh correctly, they must have the same pressure angle and pitch/module. These worms are compatible with plastic worm gears.. Speed ratio is the ratio by which output shaft speed is reduced.

.jpg)

Diamond Gear Co. Heavy Duty Motorized Worm Gear 174WG409

A worm gear motor consists of a worm screw that meshes with a worm wheel at a 90 degree angle. The worm screw has spiral threads along its length similar to a screw. As the motor turns the worm screw, the spiral threads engage the teeth of the worm wheel, causing the wheel to rotate.

.jpg)

Diamond Gear Co. Heavy Duty Motorized Worm Gear 174WG409

Martin Sprocket & Gear manufactures Power Transmission, Material Handling Solutions, and Hand Tools. Offering vast inventories & local field support. Skip to content. 817.258.3000. Worms and Worm Gears; Sheaves. QD Sheaves; Variable Pitch Sheaves; Taper Bushed Sheaves; Fractional Horsepower Sheaves; MST® Sheaves; Bushings. QD Bushings.

Helical Worm Geared Motor 040631 0.12 kW 27 rpm Sevatec GmbH

Worm Gear Motor Every type of motor has a unique purpose. The more you understand worm gearmotors, the more value you'll get out of these unique machines. Worm gearmotors have a wide variety of potential applications that makes them extremely popular with countless businesses from different industries.

.jpg)

Diamond Gear Co. Heavy Duty Motorized Worm Gear 174WG409

Worm gearboxes (speed reducers) are mechanical power transmission components that utilize a worm pinion (or screw) that is coupled with a round toothed gear (or worm wheel). As a motor turns the worm pinion, its spirals will cause the worm wheel to turn and drive a load at a reduced ratio of the supplied motor speed.

.jpg)

Diamond Gear Co. Heavy Duty Motorized Worm Gear 174WG409

A worm gear motor, as the name suggests, primarily consists of two main parts: the worm and the gear. The worm, a screw-like component, connects with the worm wheel or gear, a toothed wheel, to facilitate motion transfer. The worm is usually the driving element that, when turned, causes the gear to rotate.

wormgeardcmotorwithaluminiumwheelsforrobots3 Circuit Ideas I

Free Shipping Available On Many Items. Buy On eBay. Money Back Guarantee! But Did You Check eBay? Check Out Top Brands On eBay.

Pierce 12 Volt DC Powered Electric Worm Gear Trunk Winch — 9000Lb

Motorized Linear Slides and Rotary Stages: Two different rotary positioning stages are available with several different worm gear ratios. One has a load capacity of 100 pounds, while the other has a 1,000 pound load capacity with a large through hole that can accommodate user electrical or pneumatic cabling. Our standard linear positioning.

DC 12V Worm Gear Motor (200RPM)

A worm gear motor is known for its high torque output, compact size, and quiet operation. It operates on the principle of a worm (a gear in the form of a screw) meshing with a worm gear (similar to a spur gear). Its major advantage is the ability to reduce speed significantly while increasing torque. Maintaining Your Worm Gear Motor

.jpg)

Diamond Gear Co. Heavy Duty Motorized Worm Gear 174WG409

Worm gear motors provide unmatched torque density in a right-angle configuration enabling OEMs to develop smaller, more powerful, and highly reliable machines.

.jpg)

Diamond Gear Co. Heavy Duty Motorized Worm Gear 174WG409

Electric worm gears have transformed industries with their high torque and compact size. The invention of electric worm gears dates back to the industrial revolution when the need for compact, high-torque gear systems became apparent. Since then, these efficient gear mechanisms have been an essential part of many industries.